Professor Mohamed Pourkashanian OBE

Managing Director

We are uniquely positioned to develop and deploy CCUS and bioenergy technologies at scale, with expertise across combustion, emissions, biofuels and supercritical CO2.

We capture carbon dioxide from industrial emissions and use it to create valuable chemicals and fuels, and our facilities include advanced systems that not only remove CO2 but can also turn it into sustainable aviation fuels. We also use a first-of-its-kind Molten Carbonate Fuel Cell (MCFC) technology to generate electricity while capturing CO2 and test next-generation power systems.

Learn More

We have extensive, highly instrumented facilities to research a wide range of bioenergy sources. We analyse the gases and leftover materials from combustion and gasification to understand their properties, and we can also integrate our work with on-site carbon capture systems to explore creating net-negative carbon emissions.

Learn More

We study a variety of low-carbon fuels, including hydrogen and bio-based fuels in solid, liquid, and gas forms. By using these fuels to replace traditional fossil fuels in power generation, we help key industries reduce their carbon emissions and other harmful pollutants.

Learn More

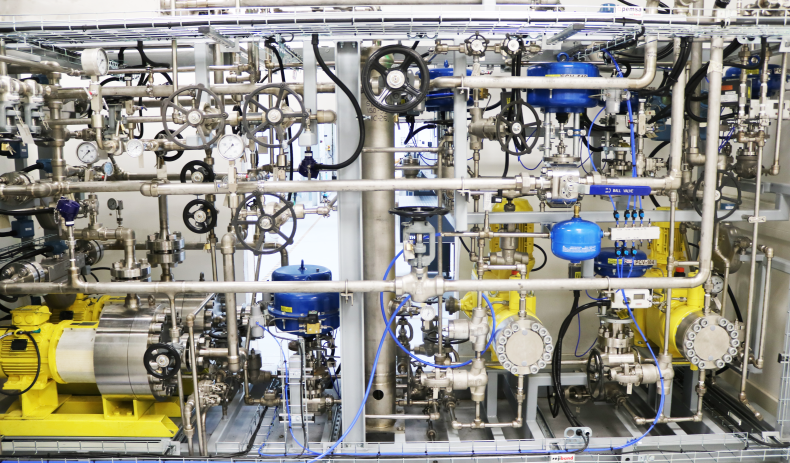

SCO2 is an incredibly versatile green solvent for a variety of industrial applications. Our SCO2 facilities can can operate at extremely high pressures and temperatures, test two heat exchangers simultaneously, and introduce contaminants to simulate real-world industrial conditions, providing crucial data for improving efficiency and longevity.

Learn More

Explore our state-of-the-art power and industrial decarbonisation facilities and equipment.

Facilities and equipmentOur team of expert academics and dedicated professional staff help to support world-leading energy research. Find out more about our expertise below.

Meet the team