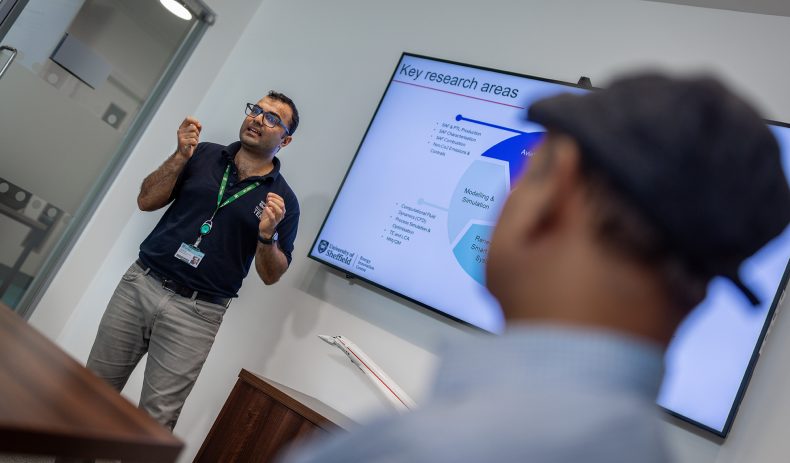

Professor Mohamed Pourkashanian OBE

Managing Director

We offer wide range of digital research methods to assist in determining the technical, financial and environmental parameters of a wide range of energy technologies.

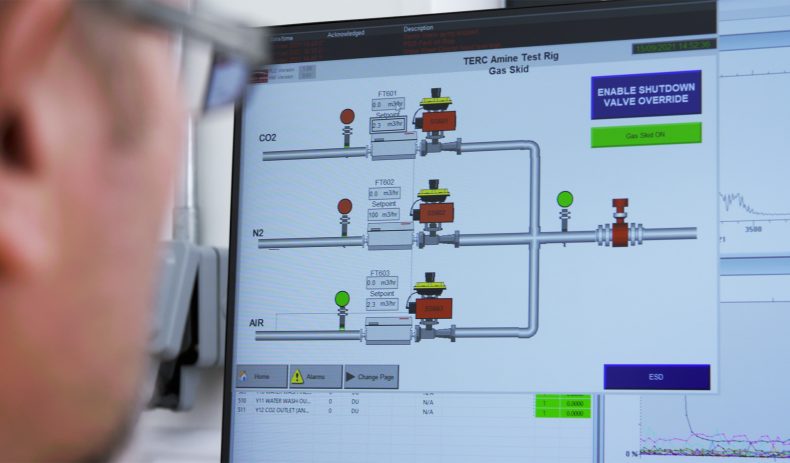

Our process modelling capabilities provide a detailed outline of a process: size, types, dimensions, duties, utilities, costs, quantifies material and energy flows. This enables improved and optimised designs, saves time and human error and can serve a basis for TEA or LCA.

Learn More

These are two methods used to study molecules and chemical reactions at the atomic level. In chemical and process engineering, they help us understand how molecules behave, react, or interact with various surfaces.

Learn More

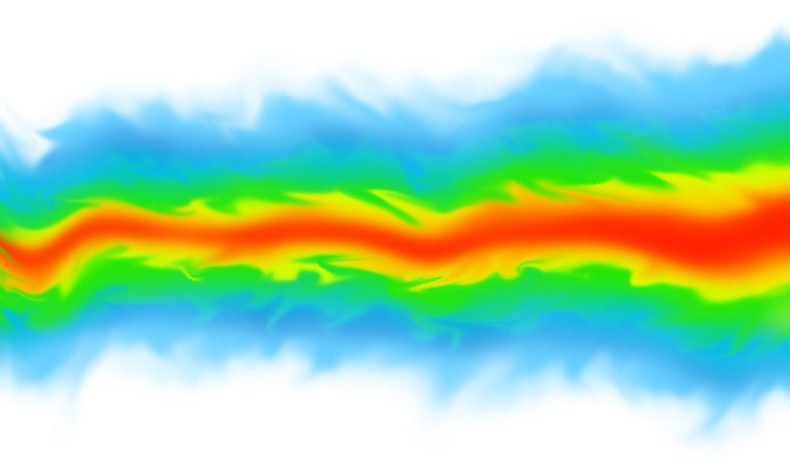

We're experts in using advanced models to understand and improve how fuel cells, hydrogen electrolysers, and CO2 separation membranes work. This allows us to optimise the design and operating conditions of these units to make them more efficient and last longer.

Learn More

We help partners evaluate the economic and environmental performance of their processes or products. We analyse costs, revenues, and profits to understand if a project is financially feasible (TEA). We also assess the environmental impacts, such as global warming potential, from raw materials to disposal to support sustainable decisions (LCA).

Learn More

Explore our state-of-the-art modelling and simulation capabilities.

Facilities and equipmentOur team of expert academics and dedicated professional staff help to support world-leading energy research. Find out more about our expertise below.

Meet the team