Hydrogen production

We research the generation of hydrogen as an energy carrier via water electrolysis from green electricity supplies (solar, imported fossil-free supply from grid) and via thermochemical processing of feedstock materials (biomass, natural gas). These methods derive high purity hydrogen gas for the purposes of testing and evaluation.

Our offering

Our pilot-scale plant allows for testing of different types of hydrogen from different sources, enabling testing that goes beyond lab-scale and can reveal key information about hydrogen energy. Our range of electrolysers are also designed for testing of hydrogen production.

We work with IMI-Vivo and their data analytics partner HySights to provide our hydrogen-production equipment.

Research interests

- Carbon intensity of UK grid supply during hydrogen production

- Alternative feedstock materials and catalaysts in alkaline unit

Hydrogen combustion and fuel switching

Our research focuses on testing, optimising and demonstrating the technologies which help to enable switching to hydrogen fuels. We support business looking to make systems modifications to deploy hydrogen infrastructure on a larger scale.

Our offering

A number of facilities at EIC can operate with either dedicated hydrogen firing or co-firing of hydrogen with another fuel. Our work ranges from burner testing to full-systems operation and facilities integration with various fuel blends. We also offer comprehensive and detailed online analysis of both systems, and we data log all relevant operating and control parameters. These facilities can operate under a wide range of conditions and turndown ratios, to enable research for a variety of energy generation and industrial applications.

Research interests

- Flame characterisation and optimisation

- Emissions monitoring, specifically NOx, including in-flame and exhaust measurements

- Heat transfer assessments

- Dedicated and co-firing of hydrogen

- Oxygen-enriched combustion environments

- Corrosion and deposition

- Hydrogen production and storage facilities; integration with carbon capture when co-firing with natural gas; analytical test suite

Hydrogen utilisation

We work with a number of partners across a range of sectors, such as technology OEMs, including burner developers and hydrogen producers, and product/systems end-users, such as power stations and industrial plant operators, to showcase and demonstrate hydrogen utilisation.

Our offering

We support your business to look at using hydrogen as an energy carrier for combustion processes and energy conversion (GT: H2 to electrical and thermal energy, pilot furnace: H2 to thermal energy). We also have facilities that support research into hydrogen as a feedstock for thermochemical processes (as a constituent of syngas and pure hydrogen to supplement reactant mixture).

Research interests

- Energy conversion

- Gasification and separation of valuable off-gases

- Combustion

- Gas-to-liquid feedstock

SAF characterisation

New aviation fuels must go through rigorous assessment before they can be brought to market. Our SAF laboratory is one of the best facilities in the UK to carry out these tests to recognised global standards including ASTM.

Assessing and characterising fuels

We partner with ambitious manufacturers and suppliers of all sizes to make sustainable aviation fuels a reality. Our state-of-the-art laboratory allows us to assess samples for a wide range of chemical, physical and thermal properties, as well as thermal oxidative stability.

ASTM-standard testing

All our work adheres to ASTM standards, including ASTM D1655, D4045, and D7566, ensuring that successful fuels are suitable for sale and use in aircraft worldwide.

SAF combustion

Our rigorous performance and emission testing enables fuel producers and users to assess the characteristics of SAF during and after combustion. We use advanced diagnostics, such as laser-based techniques, to understand how different SAF compositions affect flame behavior and emissions. This helps ensure SAF can be used safely and effectively while reducing environmental impact.

Ensure SAFs are aircraft-compatible with our jet turbine engine

Used on both Boeing and Airbus aircraft, our Auxiliary Power Unit (APU) can assess a number of emission characteristics including emissions and particulate matter measurements and gaseous emission speciation.

Research interests:

• Fuel performance and efficiency

• Engine component compatibility

• Combustion instabilities and flame dynamics

• Laser diagnostics for flame analysis

SAF and Power-to-Liquid (PtL) production

Our SAF production facilities can produce SAF from captured carbon and green hydrogen produced on site. The plant can produce hundreds of litres of fuel a day and is designed to easily try out new reactor designs and catalysts under various conditions, supporting the creation of cleaner aviation fuels.

SAF production facility

Our site is capable of producing two innovative types of SAF – Power to Liquid (PtL) and Biomass to Liquid (BtL) – using renewable energy sources which help reduce the dependency on fossil fuels in aviation.

Circular on-site systems

The plant can use CO2 captured from various sources around the facility, like biomass boilers, gas turbines, and the Waste-to-Energy (WtE) plant. This CO2 can be captured using either a solvent-based system or the molten carbonate fuel cell (MCFC).

Non-CO2 emissions and contrails

Our research focuses on how SAF affects non-CO₂ emissions like nitrogen oxides (NOₓ), particulate matter (PM), sulphur compounds and water vapour. These emissions influence contrail formation and contribute to aviation's broader climate and air quality impacts. Understanding these effects is critical for developing low-impact aviation fuels.

Reducing emission impacts

We study the impact of using SAF on both the atmosphere and local air quality by investigating the interactions of specific chemical species such as particulate matter (PM), water vapor, NO, NO₂, CO, and sulfur compounds. These species play a critical role in contrail formation and contribute to the broader environmental impact of aviation emissions.

Research interests

• Particulate matter (PM) and volatile emissions from SAF

• NOₓ and sulfur compound formation mechanisms

• Contrail precursor analysis

• Influence of fuel composition and production pathways on emissions

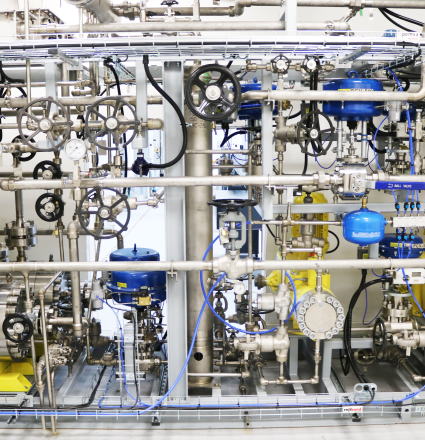

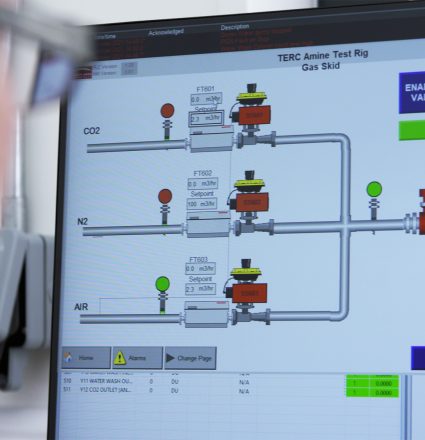

Carbon capture and utilisation

We research the different technologies for carbon capture – post combustion, pre-combustion and oxyfuel, in order to understand how carbon capture and utilisation can support the smooth, cost-effective decarbonisation of industry.

Supporting CCUS development

Our technology includes conventional and next-generation equipment, including Rotating Packed Bed solvent based CO2 capture plants, a Molten Carbonate Fuel Cell, a supercritical CO2 (sCO2) heat exchanger test bed and an amine capture plant.

Research interests

- Solvent based CO2 capture: CO2 capture from different flue gas sources, process optimisation, solvent degradation, capture plant flexibility

- MCFC: Use and generation of green hydrogen, bioenergy with carbon capture and storage (BECCS) and across the full carbon capture, utilisation (CCU) chain for both power and industrial applications.

- sCO2 rig: Study of high efficiency heat exchangers

- SAF: Testing different reactor designs and catalysts in both RWGS and FT reactors at a wide range of operational conditions. Able to separate and recycle excess/unreacted gases to enhance conversion efficiency

Bioenergy and biofuels

We research various low-carbon fuels crucial for decarbonising power generation across industries including biomass, biodiesel, sustainable fuels and syngas. We use our equipment to make comparisons of a wide range of fuels, with a particular focus on waste resource utilisation, and assessing effects on the boiler and associated equipment.

Understanding biofuels

Our system has been specifically designed for research purposes and is fitted with an array of ports within the combustion chamber and flue gas passage to allow detailed characterisation across key locations of interest. Our research focus includes flue gas and particulate matter emissions and the characterisation of metal partioning in the ash streams.

Research interests:

-

- Fuel performance and combustion characterisation comparing a wide range of biofuels and waste streams

- Metal partitioning between bottom and fly ash streams and effect on downstream CCUS plant performance

- Deposition and corrosion studies

- NOₓ and sulfur compound formation

- Particulate matter (PM) emissions

Low-carbon fuels combustion and emissions

We research the key low-carbon fuels that can be used for decarbonising power generation in a range of industries. These include hydrogen and a range of bio-based fuels, including those that are solid (biomass and bio-wastes), liquid (biodiesel and other sustainable fuels) and gaseous (biogas/syngas).

Optimising low-carbon fuels

A range of facilities on site offer testing capabilities in this area – the EfW grate boiler, biomass gasifier, biodiesel engine and our hydrogen facilities. Extensive analysis of operational parameters enable the optimisation of such systems to enhance efficiency and sustainability.

Research interests

- Greenhouse gas emissions reductions and LCA<

- Flame characterisation and optimisation

- Emissions monitoring, specifically NOx, including in-flame and exhaust measurements

- Heat transfer assessments and temperature profiling

- Dedicated and co-firing of hydrogen

- Oxygen-enriched combustion environments

- Corrosion and deposition

- Byproduct generation and analysis (quantity, composition, etc.)

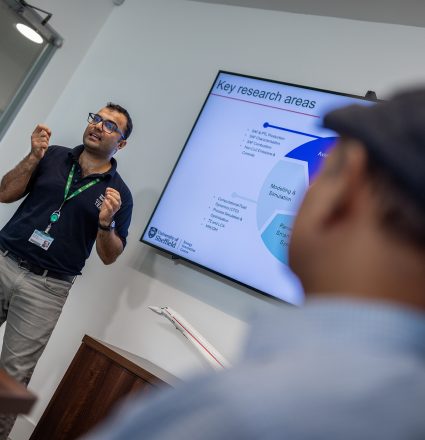

Process simulation and optimisation

Process simulation and optimisation is a method used in chemical and process engineering to model how a process works using computer software. It helps understanding how materials and energy move through equipment like reactors, distillation columns, or heat exchangers. Simulation allows the testing of different conditions without doing real experiments. Optimisation means finding the best way to run the process, for example, using less energy or making more product.

Understanding processes

We help clients by creating computer models of their chemical processes to understand how they work and identify ways to improve them. We test different operating conditions and designs, and we can produce mass and energy balances that serve as a basis for Techno-Economic Assessments or Life-cycle Assessments.

Research interests

– SAF production processes

– Hydrogen production

– CO2 capture

– CO2 utilisation

– Energy systems

– Supply chain

– Economic feasibility

– Environmental performance

– Social impact

Quantum Mechanics/Molecular Mechanics (QM/MM)

MM/QM (Molecular Mechanics / Quantum Mechanics) are two methods used to study molecules and chemical reactions at the atomic level. In chemical and process engineering, they help understand how molecules behave, react, or interact with surfaces.

Modelling options

Molecular Mechanics uses classical physics to model large molecules quickly, but with less detail. Quantum Mechanics is more accurate because it uses quantum physics, but it takes more computing time.

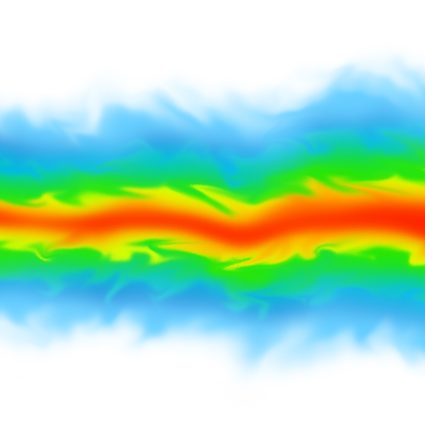

Computational Fluid Dynamics (CFD)

CFD uses powerful computers to simulate how liquids and gases move. It performs a large number of calculations to predict the fluid's behaviour, crucial for optimising chemical reactors and separation units in process engineering. CFD enhances the performance and safety of equipment like pumps and turbines, improves efficiency and reduces emissions in combustion systems.

Optimising your research outcomes

We are experts in performing multiscale and multiphysics modeling frameworks for a multitude of chemical and physical processes. The outcomes of such models are invaluable as they assist in understanding the interactions between the various physics in our rigs and optimising the operating and design parameters to maximise the efficiency and/or longevity of the unit.

Research interests

– Combustion modelling

– CO2 and NOX prediction

– Hydrogen combustion modelling

– Particulate matters transportation

Techno-economic (TEA) and life cycle assessment (LCA)

TEA (Techno-Economic Analysis) and LCA (Life Cycle Assessment) are two important tools in process design. TEA is used to assess if a process or technology is economically feasible and LCA is used to understand the environmental impact of a product or process during its whole life. Together, TEA and LCA help engineers make better decisions by considering both economic and environmental performance.

Evaluating processes

We help clients evaluate the economic and environmental performance of their processes or products. We analyse costs, revenues, and profits to understand if a project is financially feasible (TEA). We also assess the environmental impacts, such as global warming potential, from raw materials to disposal to support sustainable decisions (LCA).

Research interests

– SAF production processes

– Hydrogen production

– CO2 capture

– CO2 utilisation

– Energy systems

– Supply chain

– Economic feasibility

– Environmental performance

– Social impact