Rigs & laboratories

Explore our extensive equipment and facilities by keyword or research theme. Click the arrow on the facility to read more detailed information.

Search:

Equipment:

-

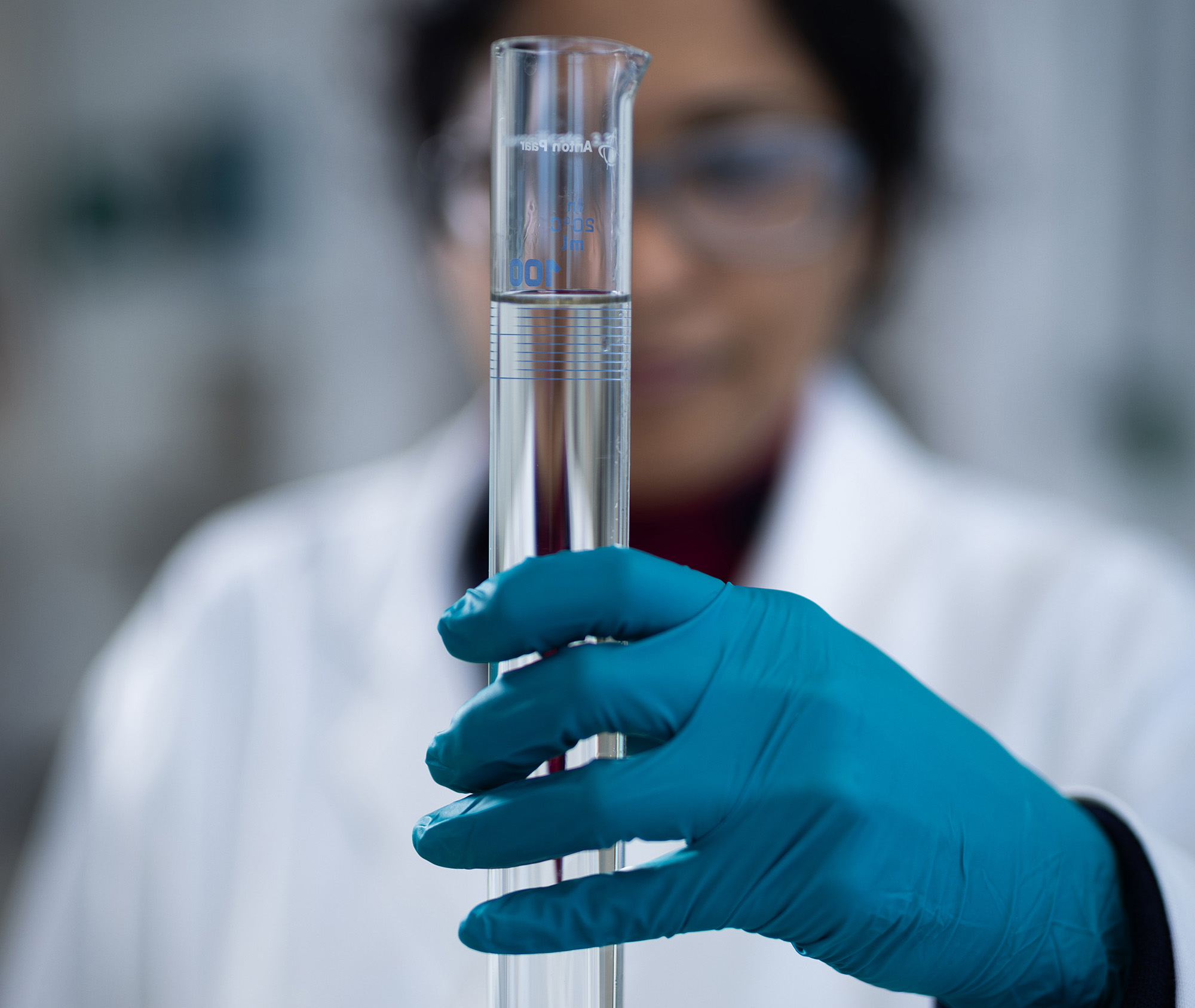

Aviation fuels testing capabilities

The EIC laboratory offers fuel testing for aviation fuels and is certified to ISO 9001:2015. Our testing methods follow recognised standard test methods, such as ASTM International, IP or UDRI wherever practicable. We are recognised by the UK SAF Clearing House as a fuel testing and pre-screening facility.

-

Electrolyser for green hydrogen

A state-of-the-art electrolyser that uses electricity to split water into hydrogen and oxygen. The uniqueness of this electrolyser lies in its ability to produce high-purity green hydrogen (99.999%) efficiently, using renewable energy generated on-site.

-

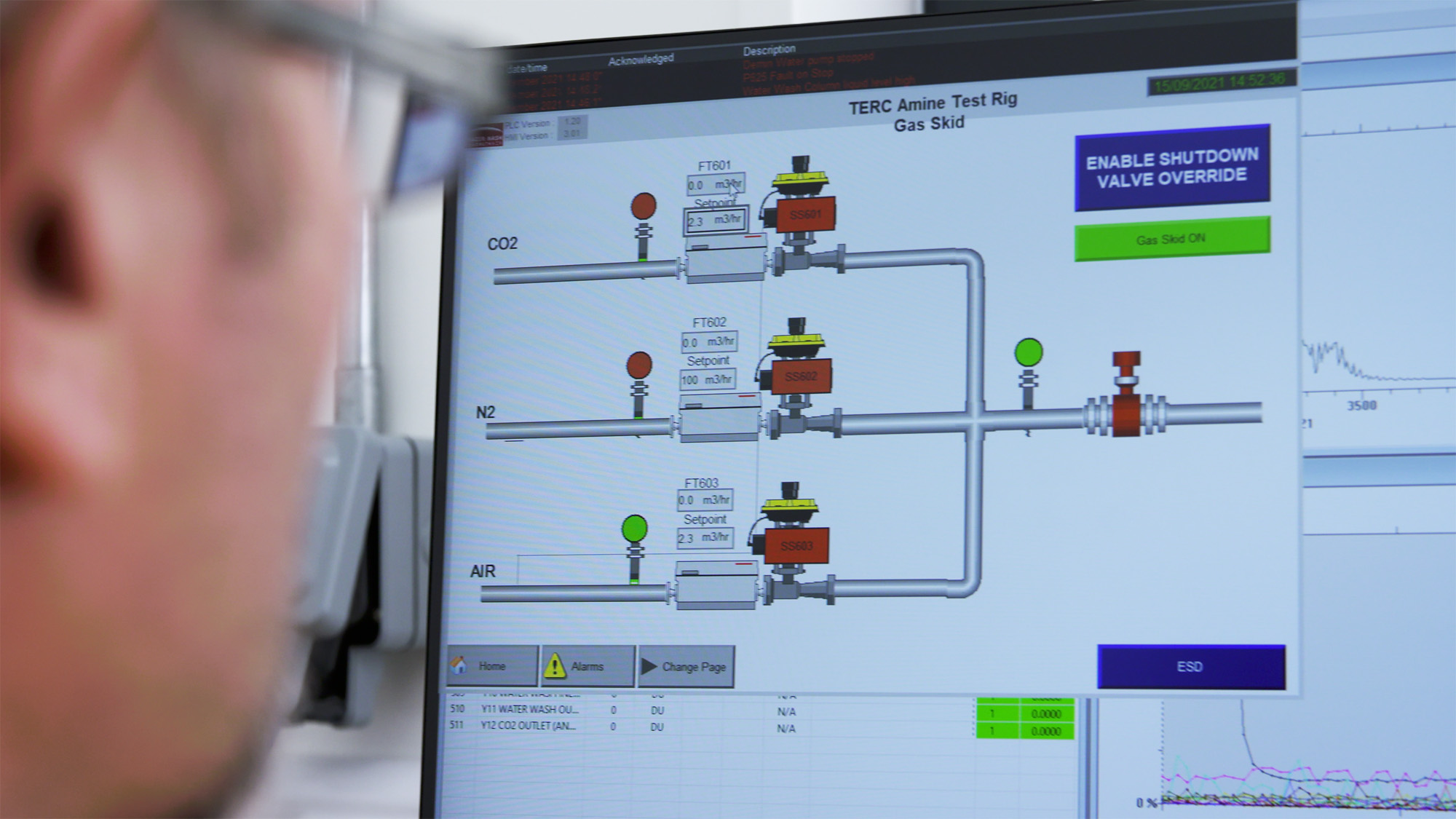

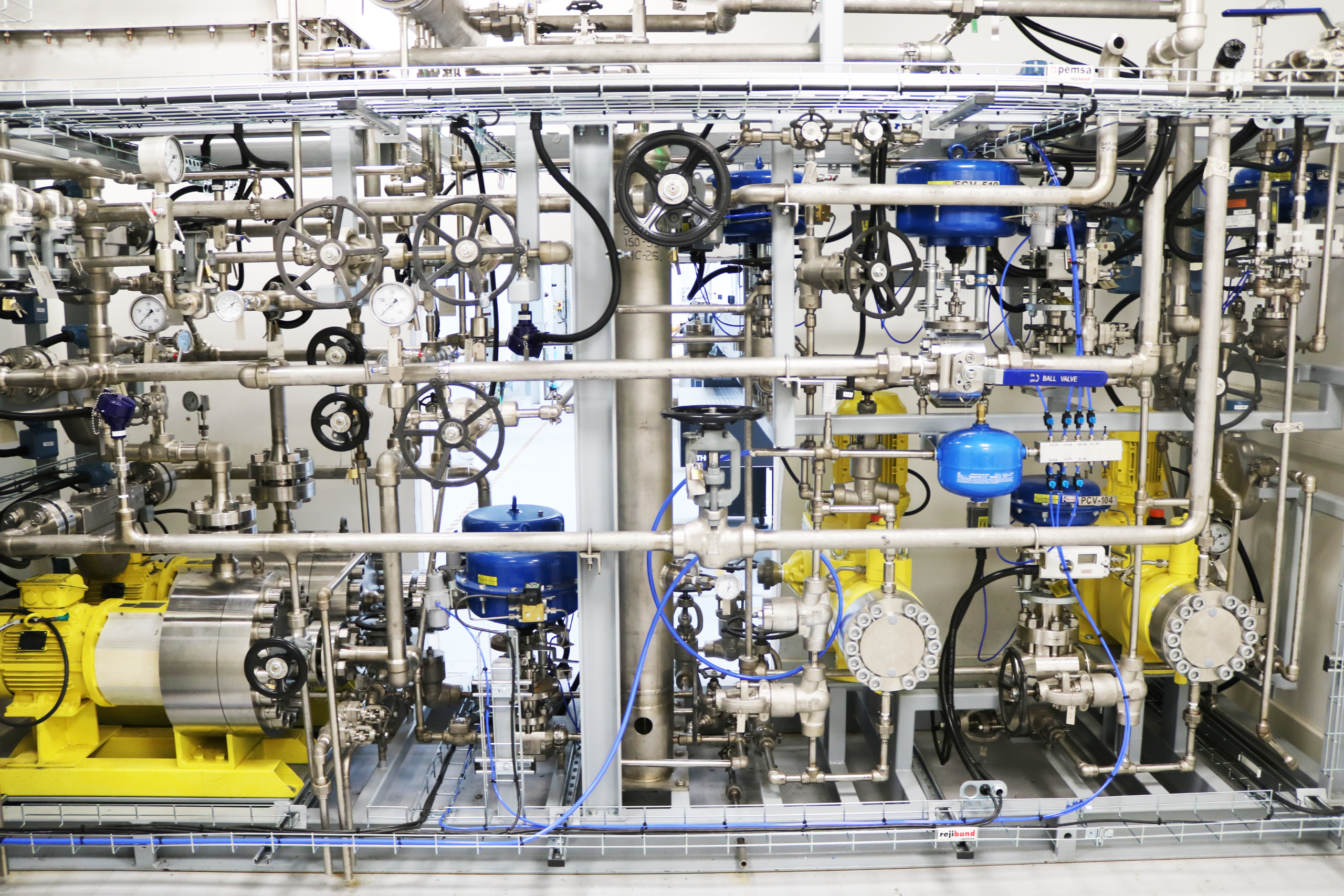

Amine solvent-based carbon capture plant

This carbon capture plant uses chemical solvents to capture CO2 from flue gases produced by combustion systems. It's capable of working with a range of gases and solvents, demonstrating flexibility in capturing CO2 from natural gas, biomass, waste and other solid, liquid and gaseous fuel emissions.

-

2-dimensional gas chromatography (GCxGC) with TOF mass spectrometry and FID

Using a tiny amount of fuel (1 ml), this instrument separates the fuel into individual components before determining the type of molecule (mass spectrometry) and concentration (FID) of each component. Due to the two-dimensional GCxGC, components with similar boiling points but different polarities can be resolved.

-

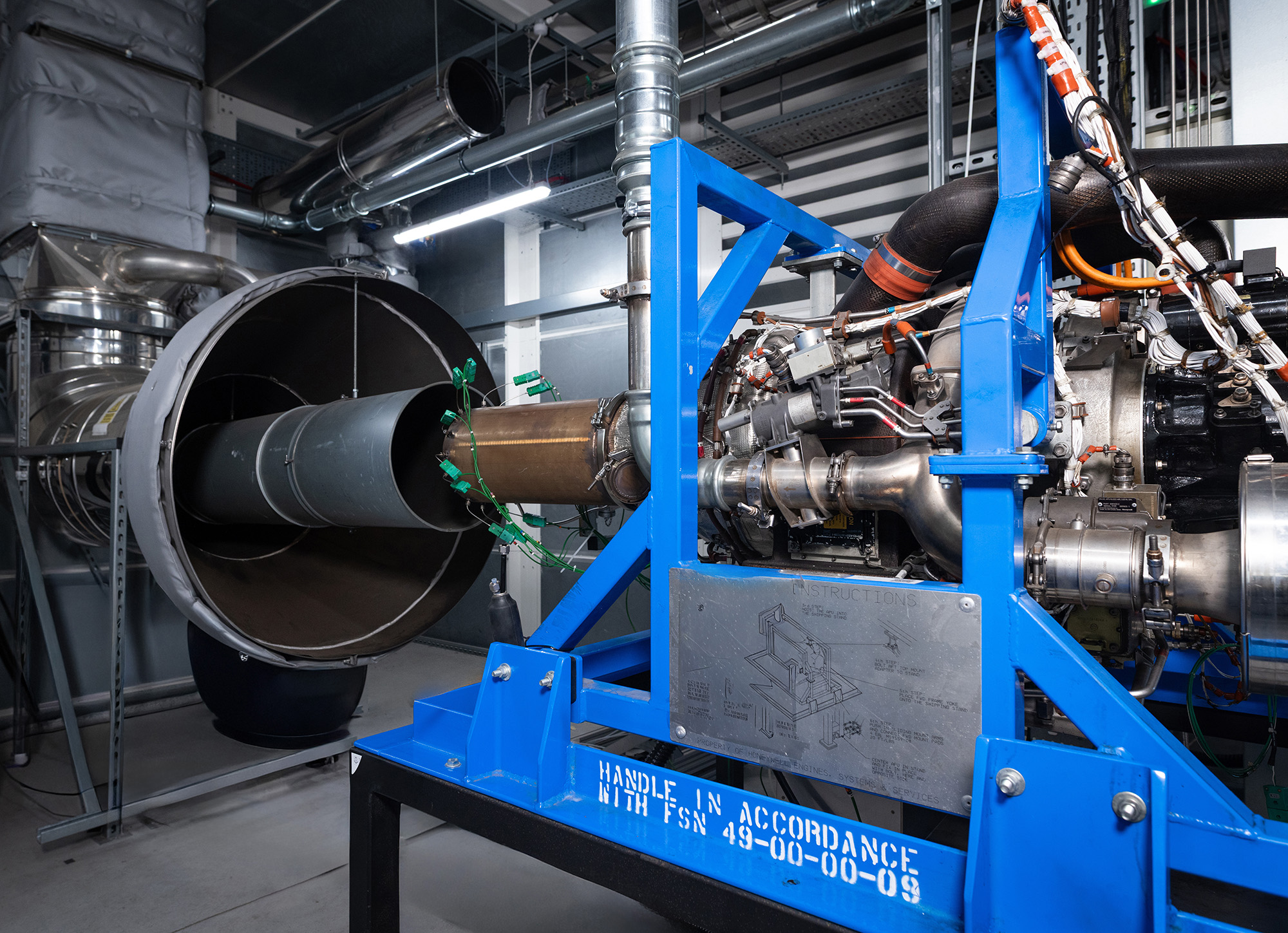

Auxiliary Power Unit (APU)

The APU can simulate real-world aircraft fuel testing conditions, providing invaluable data for validating medium-pressure combustion models and understanding the environmental impact of different fuels, as well as assessing any new emission measurement technology.

-

Organic Rankine Cycle (ORC)

The Organic Rankine Cycle (ORC) is a thermodynamic power cycle which uses an organic fluid to convert heat into electricity, Similar to the commonly-used steam Rankine cycle, the working fluid in the ORC is heated to produce high pressure gas, which is discharged through a turbine expander in order to produce mechanical work and generate electricity,

-

Smart energy system

The different technologies at this facility can be combined into integrated systems in an effective and complementary manner, in order to make our energy use efficient and sustainable.

-

Solar PV Panels

We have several solar PV panels situated on the roof that we use to generate green energy for the site. That energy can then be linked to our batteries and electrolyser to produce green hydrogen.

-

Energy storage batteries

Our facility hosts 120kWh, 50Kw Lithium battery with DC and AC interfaces that can be connected to the AC grid for grid-connected research, or to a dedicated DC bus along with other assets to provide a flexible test bed to facilitate both grid-connected and ‘behind the meter’ energy optimisation.

-

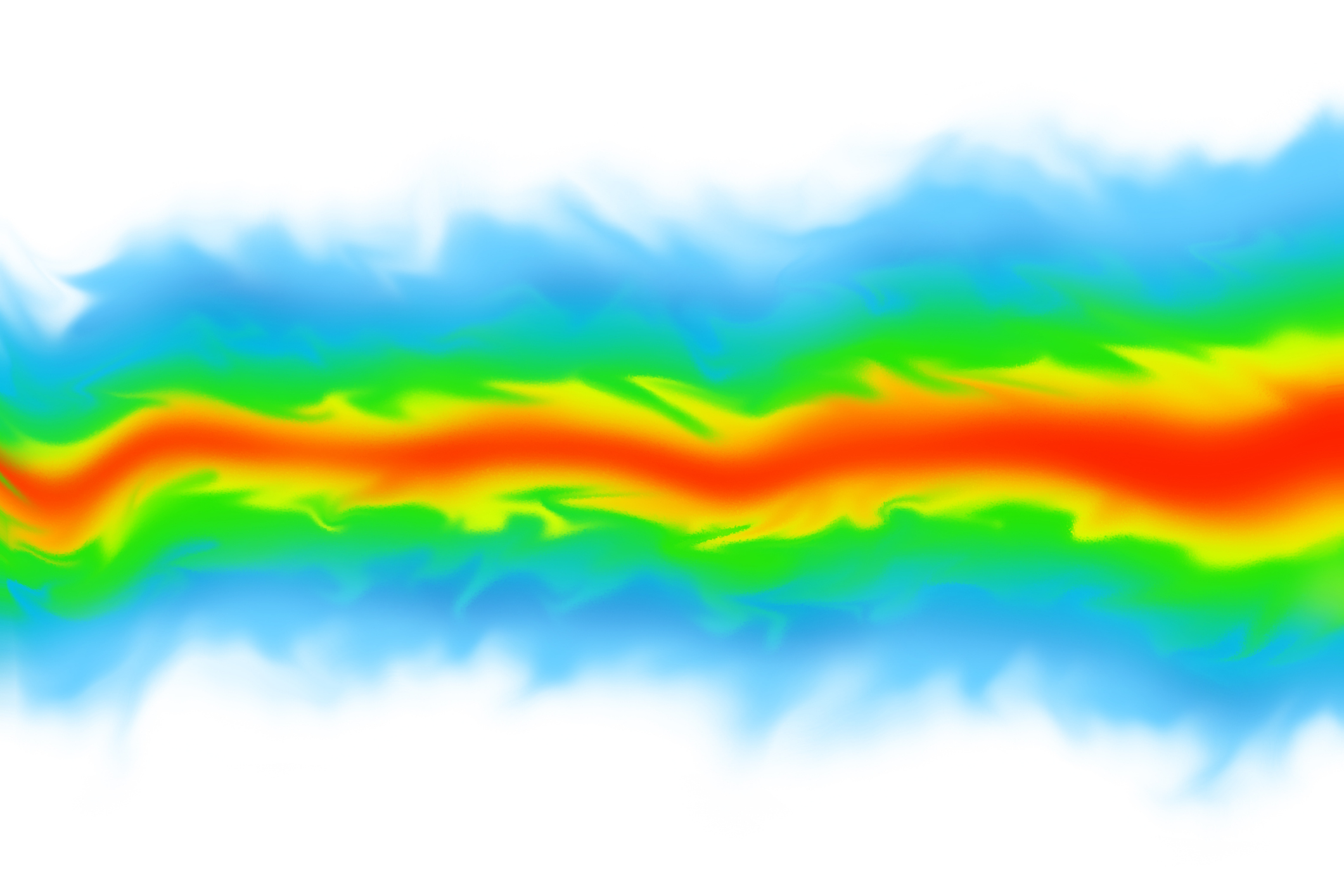

Computational Fluid Dynamics (CFD) modelling and simulation

We can provide a range of complementary validating systems, including advanced computational modelling, experimental testing and detailed imaging.

Multiple modelling stations pre-loaded with relevant software including CAD Drawing, Fluent, Aspen, Chemical Kinetic, Matlab/Simulink.

This equipment ensures a credible output and in-depth understanding and control of the impact of energy system characteristics and integration, critical reaction kinetics, emissions and combustion processes.

-

Advanced Molten Carbonate Fuel Cell (MCFC)

We are home to a state-of-the-art, low-carbon energy research rig which is the first of its kind in the UK. The MCFC enables research into an innovative method of capturing up to 90% of CO2 while simultaneously producing both electricity and hydrogen.

-

High-resolution ELPI measurement instrument

Our High Resolution ELPI®+ can provide key information on the distribution, concentration and chemical composition of particles present in SAF and other sustainable fuels.

-

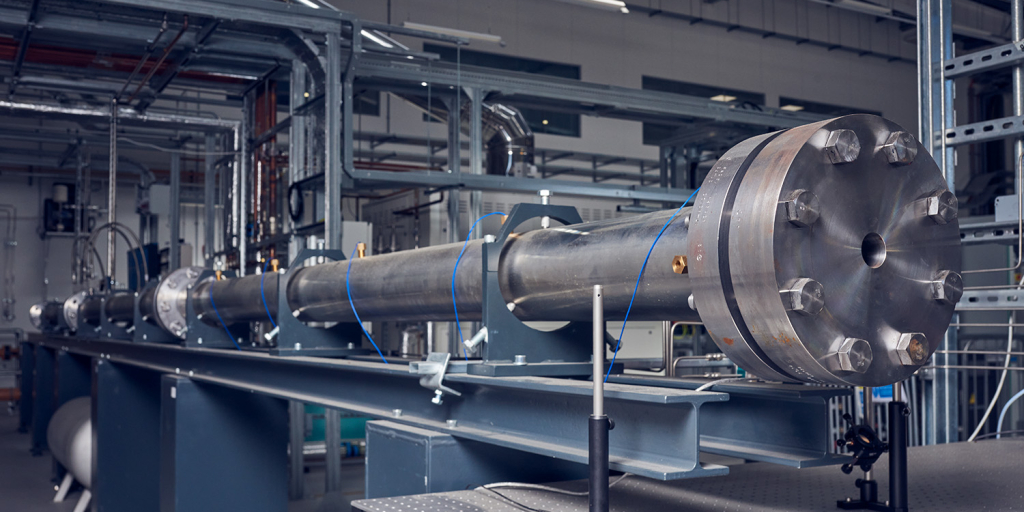

Shock tube

- A unique high pressure (up to 100 bar) single pulse shock tube with extended drivers

- State-of-the-art laser diagnostic facilities

- For chemical kinetics measurement of sustainable alternative fuels

- Investigation into the chemistry which takes place during pyrolysis and oxidation of sustainable fuels

- Kinetics of branched chain reactions to define ignition

-

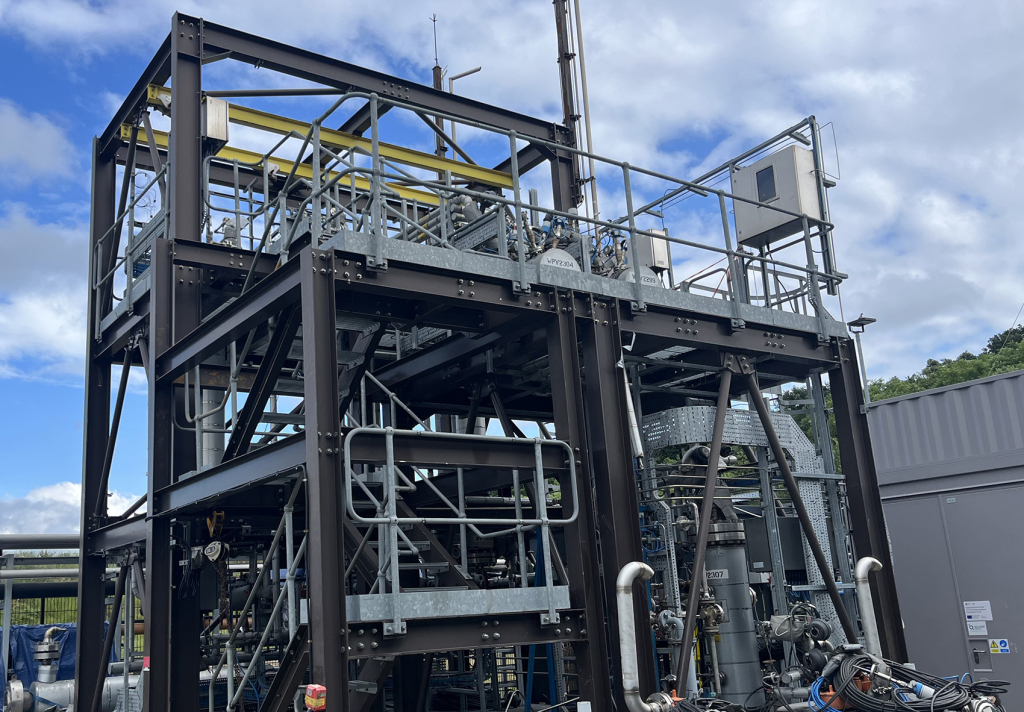

Power-to-Liquid pilot plant with Fischer-Tropsch and Reverse Water Gas Shift (RWGS)

Our pilot plant can produce sustainable fuel in two ways: by using CO2 captured from the air or from gases and green hydrogen (Power-to-Liquids), or from syngas produced by biomass gasification (Biomass-to-Liquid).

-

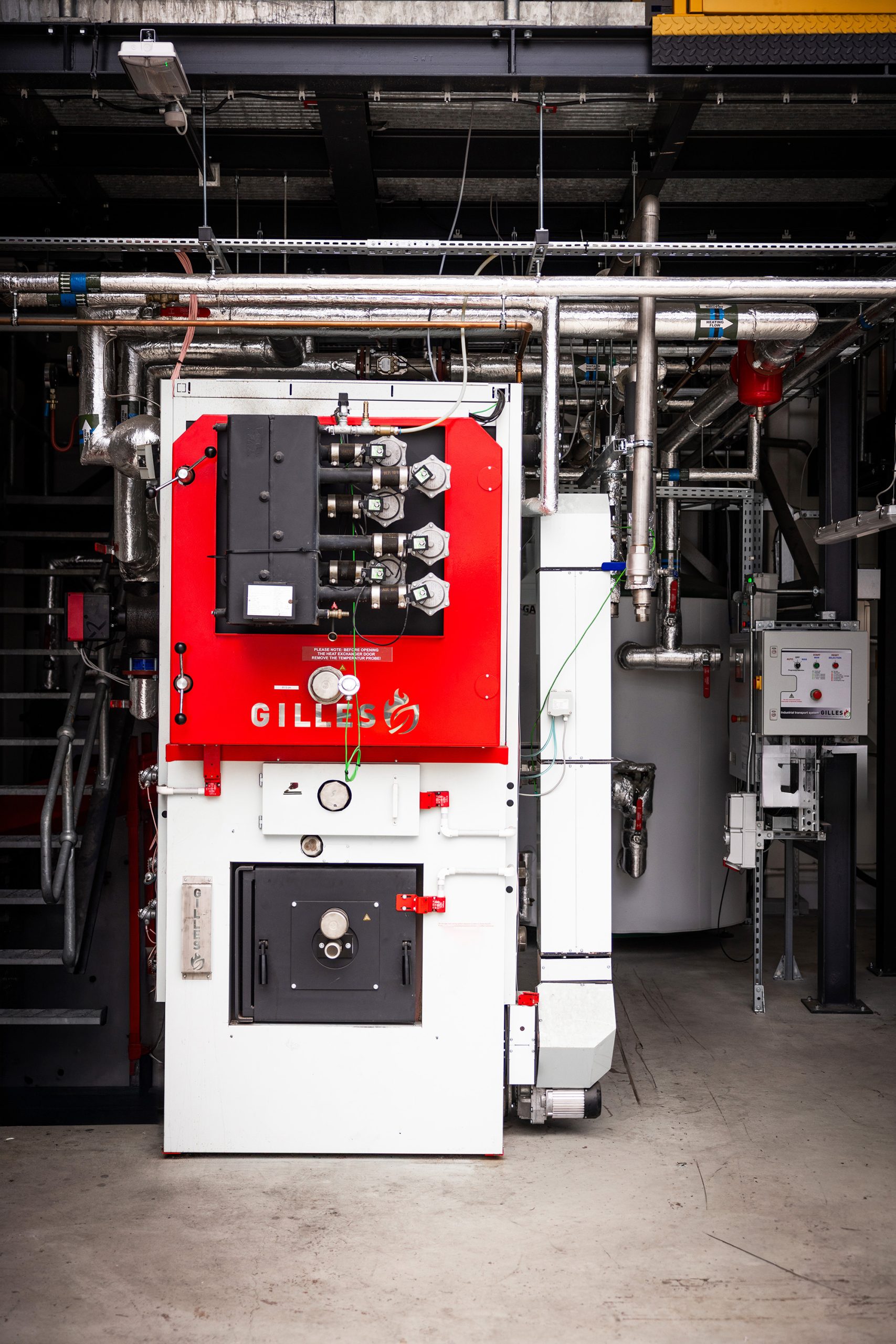

Bioenergy/Waste-to-Energy Grate Boiler

This boiler is designed to test and compare the combustion characteristics of various biomass fuels and biomass-derived wastes and residues.

-

Analytical and measurement laboratory capabilities

We have a range of analysers and probes for emissions testing and detection.

-

Emissions monitoring facilities

We can undertake online bulk gas emissions assessments for flue gases, including CO2, CO, O2, NOx, SOx and unburned hydrocarbons, via a range of standard methods.

-

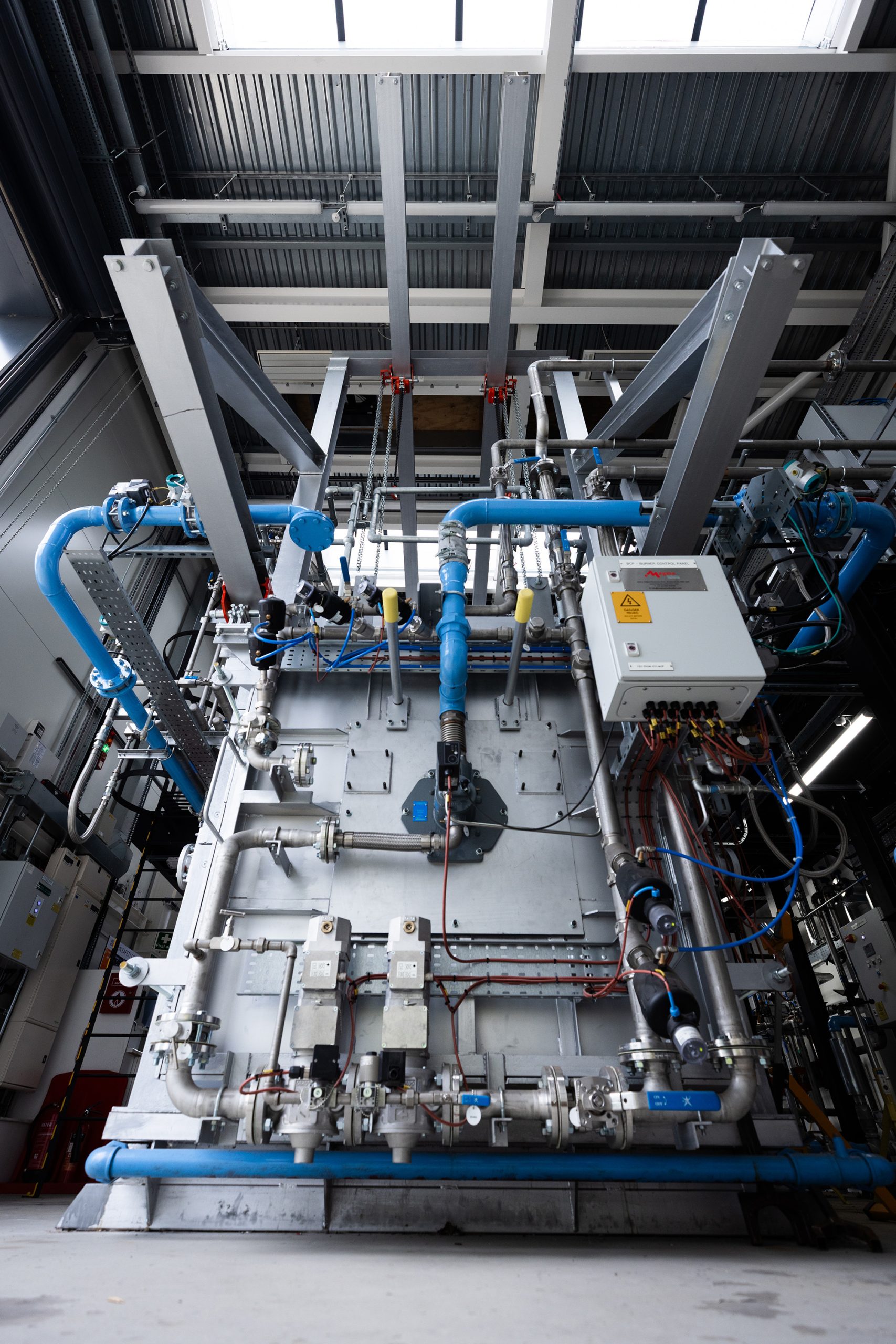

Supercritical CO2 (sCO2) heat exchanger test bed

This device uses supercritical CO2 as a working fluid resulting in higher efficiencies and lower energy losses due to relatively higher energy recovery potential.

-

Micro CHP

A novel engine that combines the generation of electricity and heat in one process, using a variety of fuels, this micro-CHP system is designed to be highly efficient, offering both electrical and thermal power outputs.

-

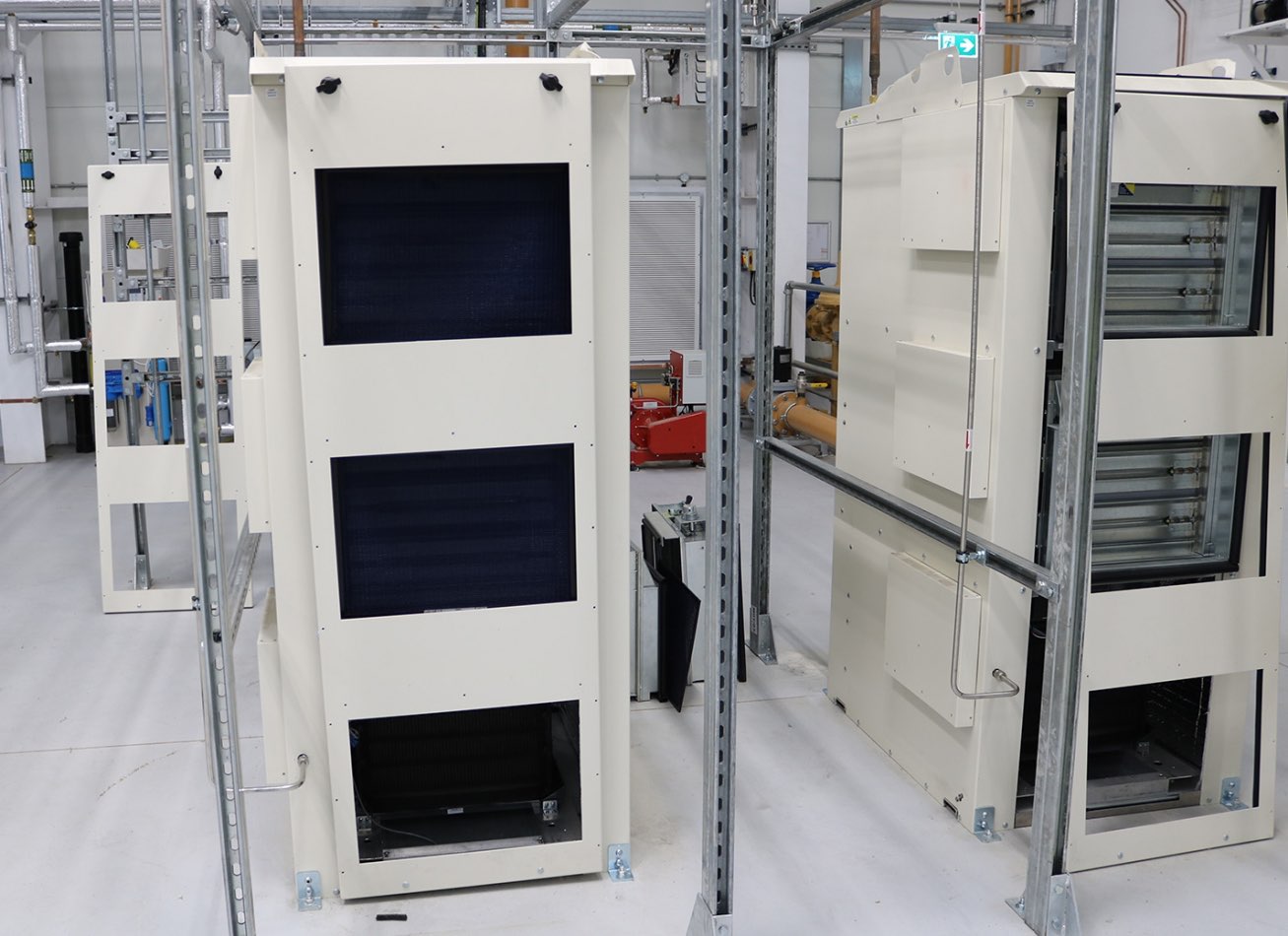

Multi-parameter fuel cell test station

This multi-parameter fuel cell test station can investigate the impact of operating conditions, such as temperature, pressure, gas composition and humidity, on single fuel cell or small fuel cell stacks.

-

PEM fuel cell

This PEM fuel cell uses green hydrogen to produce clean electricity, with our particular system being able to generate up to 15kW of power from each fuel cell, achieving a conversion efficiency over 50%.

-

Hydrogen combustion research facility (HCRF)

Tailored for R&D activities, the HCRF can undertake a wide range of analytical functions, including near burner analysis, heat transfer to load and furnace analysis, emissions analysis and burner design and performance analysis, as well as many other functions.

-

IMI VIVO electrolyser for green hydrogen

As well as the alkaline electrolyser, the EIC also hosts a unique PEM electrolyser supplied by IMI VIVO.

-

Combined Heat and Power (CHP) Biomass Gasifier

This gasifier can designed to produce clean syngas for heat and power generation from biomass fuels with a low tar content. It is integrated with both on-site CO2 capture and utilisation facilities Fischer-Tropsch plant, enabling liquid biofuel production, particularly jet fuels.

-

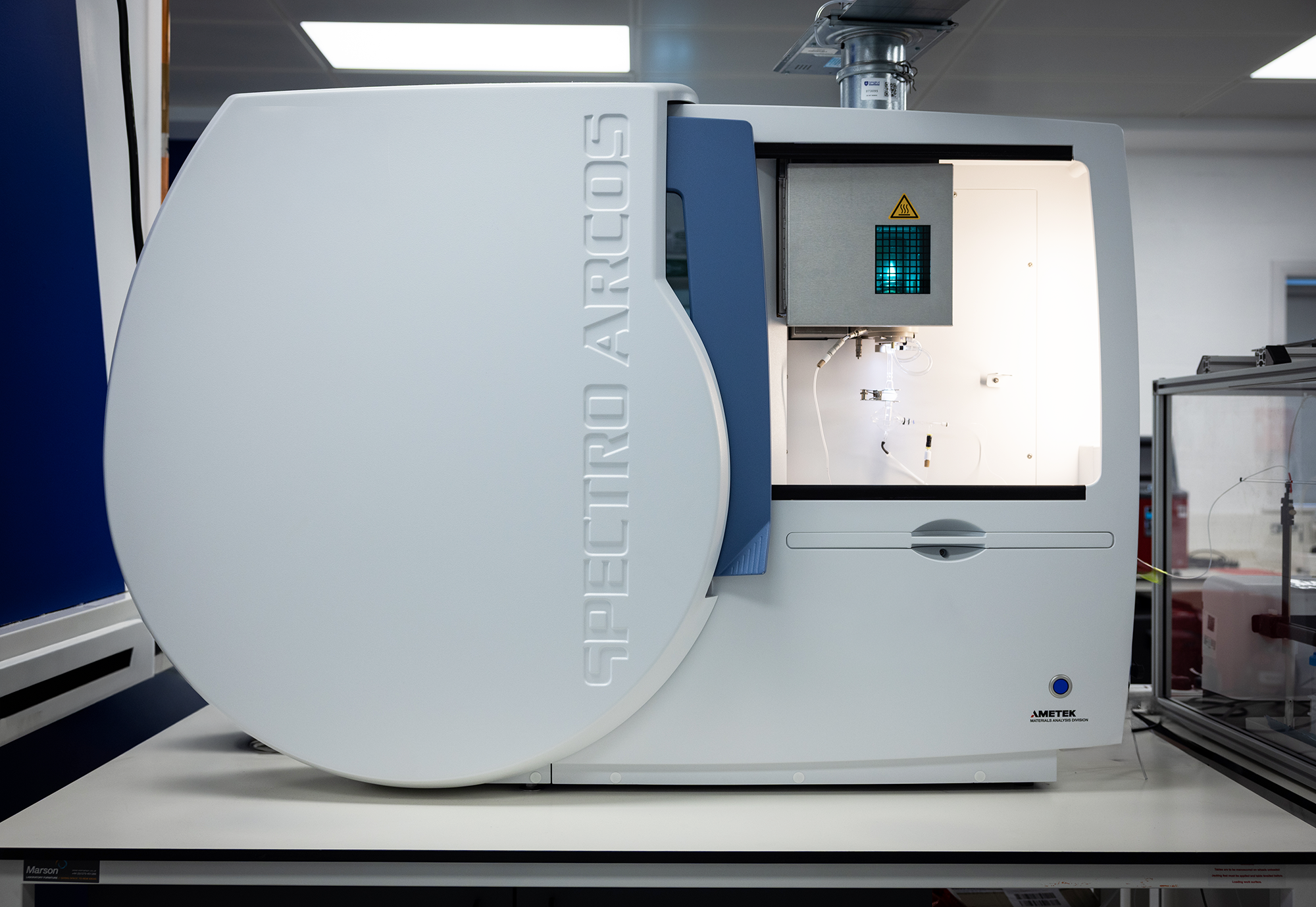

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

Our SAF laboratory houses an ICP-OES used for the pre-screening of fuels, to quantify the species and concentrations of metal contaminants present.

-

Biodiesel engine generator

Our biodiesel system is able to support research into a variety of liquid biofuels, facilitating the assessment of key performance indicators and enabling the innovation and development of cleaner liquid fuels for a range of applications, including power generation, industry and transport.

-

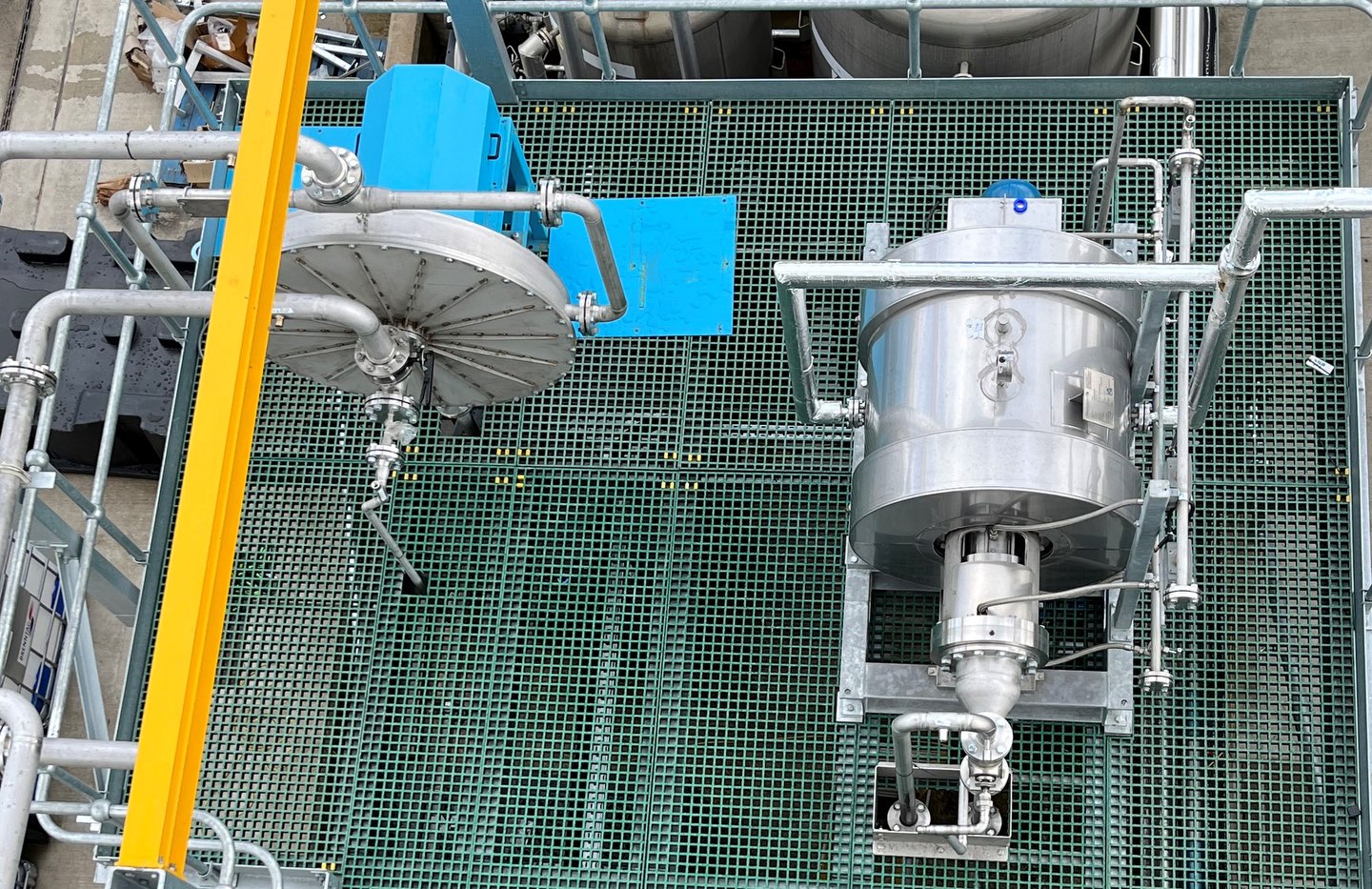

CO2 capture rotating packed bed (RPB)

This next generation-RPB capture plant is designed for advanced research on capturing CO2 from different types of flue gases (gas, coal, biomass, industrial gases).

-

Gas turbine

This state-of-the-art gas turbine is designed to generate both electricity and heat from a variety of fuels, and is tailored for high-efficiency operations with minimal emissions.

Let's work together

Get in touch

Sheffield Business Park

Europa Avenue

S9 1ZA