A promising pathway to decarbonising aviation

Our site is capable of producing two innovative types of SAF – Power to Liquid (PtL) and Biomass to Liquid (BtL).

These low- and zero-carbon aviation fuels are produced using renewable energy sources and captured carbon dioxide, helping to not only reduce the sector’s dependency on fossil fuels but also remove harmful CO2 from the atmosphere.

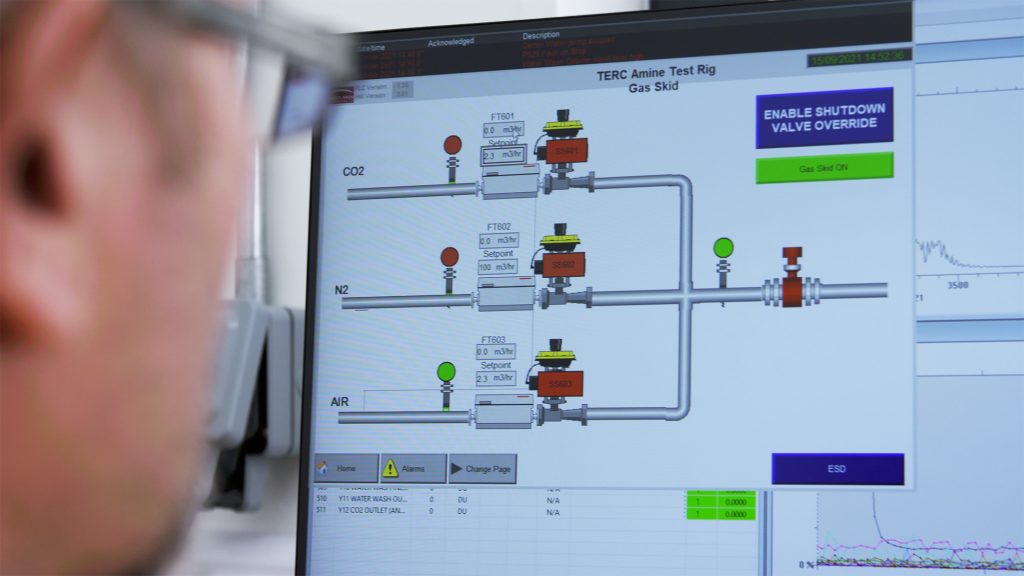

- In the PtL process, carbon dioxide and green hydrogen are converted into ‘syngas’ in a Reverse Water Gas Shift (RWGS) reactor. This syngas is then converted to jet fuel in a Fischer-Tropsch (FT) reactor.

- In the BtL process, biomass is gasified to produce syngas followed by conversion to jet fuel in the FT reactor.

- We are also exploring new innovations in SAF production, such as the hybridisation of PtL and BtL with carbon capture and storage (PBtL-CCS).

The largest capacity to produce green hydrogen of any UK university

Our two electrolysers can produce up to 150m³/h of green hydrogen, as well as additional blue hydrogen production capabilities.

The hydrogen produced on-site can then be utilised to produce SAF and other sustainable fuels.

No matching posts found.

Related research

Explore our expertise in similar research areas.

View all